|

Iron Fireman Manufacturing Company During World War Two

Portland, OR

1923-1974 when purchased by Boeing

Cleveland, OH

1929-2000

Franklin Park,

Illinois

2000-2011

This page updated 12-8-2024.

What a cool and unique vehicle! I

almost did not take the opportunity to see and learn about this at the

MVPA-HA National Convention at Oshkosh, WI which took place August

12-14, 2024. I had been debating for the past several weeks as to

whether I wanted to make the long journey to the convention. I was

unsure of how it would provide anything new of interest to me. Of

late, MVPA conventions and shows, both national and local, have seen a

decrease in World War Two vehicles and an increase in more modern

military vehicles. I am interested in World War Two vehicles and

the post war military vehicles are not of much interest to me. In

the end, I decided to make the trip because there was also the EAA

Museum, and the Military Veterans Museum located within a couple of

miles of where the MVPA convention was being held on the EAA grounds.

Both of these museums, along with the few added items I saw at the MVPA

convention, made the trip worthwhile.

Had I not gone, I would never have seen this

very unique T36 snow tractor built by the Iron Fireman Company of

Portland, OR. I would not have learned about the company, had a

chance to research it, nor learn how it helped win World War Two.

While the T36 is an interesting product, the company produced 7.6% of

the 2,500 hp triple reduction steam engines used in the very important

Liberty cargo ships of World War Two. The Liberty ship engines

were where the Iron Fireman Company made the most important contribution

to winning World War Two.

When I first saw the company name of Iron

Fireman, I thought of a firefighter. But the name of the company

goes back to when coal was the main heating fuel in the United States.

The "Fireman" in the name references the person who stoked and fed coal

into the furnace. Steam locomotives all had an operator called a

fireman to do this. Once I learned that the company made

mechanical stokers, its name made sense. It is also a name that is

easily remembered.

The company's logo consisted of an iron

fireman shoveling coal.

The History of Iron

Fireman:

In 1923 Thomas Harry Banfield and Cyrus Jury

Parker took over an iron works in Portland, Oregon that was

manufacturing a small coal stoker that automatically fed coal to the

furnace. Relatively quickly, they found out it didn’t work very well, so

the men redesigned it and named it the Iron Fireman®. U.S. Patent and

Trademark Office (USPTO) records indicate that, according to information

provided by the company, the name and logo were first used, and first

used in commerce, on July 1, 1923. The USPTO records also suggest that

the name and logo were first registered as trademarks sometime in 1925.

Relatively quickly, it became a commercial success. In 1928 both men

were involved in an air crash which claimed Parker’s life. Banfield

recovered and succeeded Parker in company leadership.

The automatic coal stokers were used for both

residential and commercial building furnaces. The product designed

for homes, which was called the Iron Fireman Jr., eliminated the need for someone to have

to periodically shovel coal into the furnace, all day and all night. We

did not have one of these in our first house, which was originally coal

fired. I remember going down in the basement when I was really

young to watch my father shovel coal into the furnace from the coal bin.

He also had a long steel rod with a hook on the end of it to stoke the

fire. My parents converted to natural gas just before or while I

was in kindergarten.

In industry, it was a labor savings as men

were no longer needed to tend fires and stroke the steam boilers. Coal

was the heating fuel of choice for the first half of the century in this

country. Therefore, the Iron Fireman was a product sought after by

both home owners and commercial companies.

In 1945, the coal stoker business of the

Portland plant was moved to Cleveland, OH and consolidated with that

plant's oil burner business. However, this was not the end of the

Iron Fireman plant in Portland. The plant switched product lines

and began making aerospace products for Boeing aircraft and USAF guided

missiles. The Portland site became known as the Portland Division

of the company. In 1961 the company merged with the

Electronic Specialty Company (ESCO). After the merger, the

Portland plant continued to produce aerospace components until it was

purchased in 1974 by Boeing.

Following World War Two, the company developed oil fired burners at

their Cleveland facility and consolidated the business at that location.

By 1960 Iron Fireman had a commanding presence in commercial power

burner sales – reportedly about 60% of the US market. Because coal had

lost its place as the major heating fuel to oil and natural gas, the

coal stoker business was sold to the Will-Burt company in 1966.

In 2000

Iron Fireman was acquired by Vapor Power, who moved operations to

Franklin Park, Illinois. It operated there until production ceased in

December 2011. Vapor Power then sold all remaining assets for

burners of the Iron Fireman business to OEM Boiler Parts Inc., of

Elizabethtown, PA, including all engineering and sales records, parts

inventory, and production tooling.

This

page will focus on the original Portland, OR operation of the company.

The Iron Fireman Manufacturing Company's World War Two Products:

Even before the United States entered World War Two, the Iron Fireman

Manufacturing Company was making both aluminum and steel machined

components for use on Boeing B-17 Flying Fortresses. In August

1940, Boeing was awarded a $130,000,000 contract from the USAAF for 512

B-17Es. The Iron Fireman Manufacturing Company then received a

$1,200,000 contract from Boeing to produce 700 machined part numbers for

the 512 B-17Es. The Iron Fireman Manufacturing Company then

purchased 100 machine tools worth $250,000 to be able to produce the

parts for Boeing. By April 1941, the company had 200 machinists

working 24 hours a day, five days a week, turning out the B-17

components. Concurrently, the company also had 200 workers making

coal stokers. The Iron Fireman Manufacturing Company also

purchased a second plant with 16,000 square feet of floor space for its

new machine tools.

The first defense contracts awarded to the

Iron Fireman Manufacturing Company were with the Boeing Company to

produce 700 different machined parts, both steel and aluminum for

the 512 B-17Es like this one on display at the National WWII Museum in

New Orleans, LA. Image courtesy of Ronyeh.

Table 1 shows that the Iron Fireman

Manufacturing Company's Cleveland, OH plant was awarded $2,163,000 in

major contracts during World War Two. Table 2 shows that the

Portland, OR plant had $42,878,000 in major contracts during the war.

Its largest contract was for $36,875,000 for the engines used in the

Liberty ships. This one contract was 86% of the total major

contracts the company received for the war effort. Table 4

indicates that the Iron Fireman Manufacturing Company produced 209

Liberty ship engines in 15 months during 1942-43. This was 7.6% of

the total engines required.

In 1942, the company became one of twenty

companies that formed Oregon War Industries, Inc. in Portland, OR.

This organization pooled resources in order to obtain war contracts that

the smaller companies may not have been awarded on their own. It

also allowed member companies access to other company's facilities when

needed to complete a contract.

The Iron Fireman Manufacturing Company is

another prime example of many companies during World War Two that

manufactured products totally unrelated to their peacetime product line.

The company's production of B-17 aircraft components, 250,000 lb.

Liberty ship engines, snow tractors, and bomb fuzes shows that the

company produced a wide variety of products to help win World War Two

totally unrelated to its peacetime coal stokers.

Table 1 - Iron Fireman

Manufacturing Company's

Major World War Two Contracts - Cleveland, OH Plant

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division, Requirements and Progress

Branch January 21, 1946. |

|

Product |

Contract Number |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Mounts Gun -

Army Ordnance |

303-ORD-1201 |

$595,000 |

1-1942 |

9-1942 |

| Mounts Gun -

Army Ordnance |

303-ORD-1493 |

$705,000 |

4-1942 |

11-1942 |

| Metal Amm

Containers - Army Ordnance |

33019-ORD-1475 |

$500,000 |

2-1944 |

12-1944 |

| Salvage

Equipment - Maritime Commission |

WSA-1331 |

$259,000 |

12-1944 |

6-1944 |

| Riveting Gun

Kits - Army Corps of Engineers |

30082-ENG-4966 |

$104,000 |

3-1945 |

5-1945 |

| Total |

|

$2,163,000 |

|

|

Table 2 - Iron Fireman

Manufacturing Company's

Major World War Two Contracts - Portland, OR Plant

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration,

Industrial Statistics Division, Requirements and Progress

Branch January 21, 1946. |

|

Product |

Contract Number |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Equipment

Armament - USAAF |

535-AC-16388 |

$87,000 |

11-1940 |

6-1941 |

| Assemblies

Mount - USAAF |

535-AC-22344D |

$582,000 |

11-1941 |

11-1942 |

| Shopwork -

Navy |

NOS-95948 |

$50,000 |

12-1941 |

6-1942 |

| Gun Parts -

Army Ordnance |

741-ORD-11442 |

$57,000 |

12-1941 |

9-1942 |

| Gun Parts -

Navy |

120-S-15254 |

$77,000 |

1-1942 |

3-1942 |

| Ordnance

Material - Navy |

120-S-15494 |

$95,000 |

2-1942 |

7-1942 |

| Marine

Engines - Maritime Commission |

4678 |

$36,875,000 |

3-1942 |

3-1944 |

| Ordnance

Material - Army Ordnance |

741-ORD-13139 |

$134,000 |

5-1942 |

1-1943 |

| Valves - Navy |

NXS-25793 |

$1,991,000 |

3-1943 |

3-1944 |

| Bomb Tail

Fuzes - Army Ordnance |

42000-ORD-281 |

$700,000 |

3-1944 |

10-1944 |

| Snow Tractors

T36 - Army Ordnance |

42000-ORD-483 |

$518,000 |

7-1944 |

2-1945 |

| Bomb Tail

Fuzes M101A2 - Army Ordnance |

42000-ORD-642 |

$1,134,000 |

9-1944 |

6-1945 |

| Bomb Tail

Fuzes - Army Ordnance |

42000-ORD-951 |

$578,000 |

1-1945 |

8-1945 |

| Total |

|

$42,878,000 |

|

|

Table 3 -

Iron Fireman Manufacturing Company Vehicles

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

Contract Number |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Tractor, Snow,

T36 |

42000-ORD-483 |

|

|

|

|

36 |

|

36 |

|

Table 4 -

Iron Fireman Manufacturing Company World War Two Liberty

Ship Engine Production |

|

Month |

Quantity |

|

1942 |

|

|

June |

2 |

|

July |

4 |

|

August |

5 |

|

September |

6 |

|

October |

8 |

|

November |

10 |

|

December |

12 |

|

1942 Total |

47 |

| |

|

|

1943 |

|

|

January |

14 |

|

February |

14 |

|

March |

16 |

|

April |

20 |

|

May |

22 |

|

June |

24 |

|

July |

25 |

|

August |

27 |

|

1943 Total |

162 |

| |

|

|

Grand Total |

209 |

2,750 Liberty ships were

built during World War Two. The 209 engines the Iron Fireman

Manufacturing Company produced was 7.6% of the total needed.

Each ship had one engine.

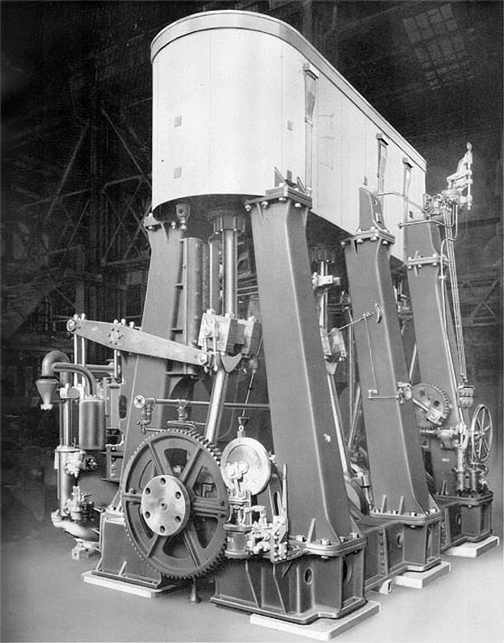

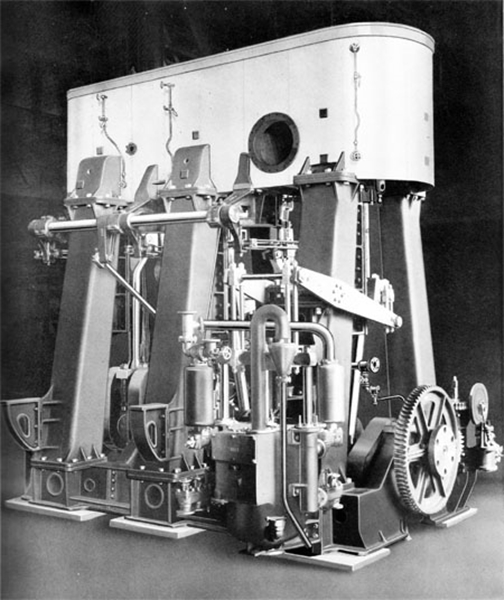

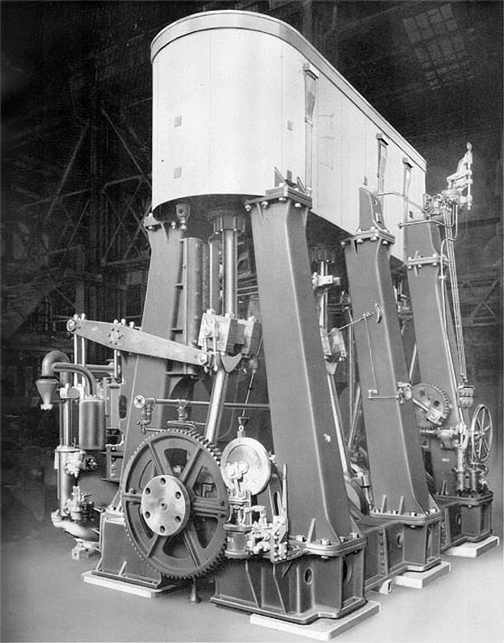

The engines were 23 feet in height and

weighed 250,000 lbs. There were 15,542 individual parts in the

engine. This was not like anything the company had produced in

peacetime and shows the Iron Fireman Manufacturing Company's ability to

adapt and then build such a massive device. Image from

Instructions for the operation and maintenance of 2500 I.H.P.-24

1/2-37-70 x 48"-76 R.P.M. vertical triple expansion marine steam engines

for the United States Maritime Commission EC2-S-C1 cargo vessels.

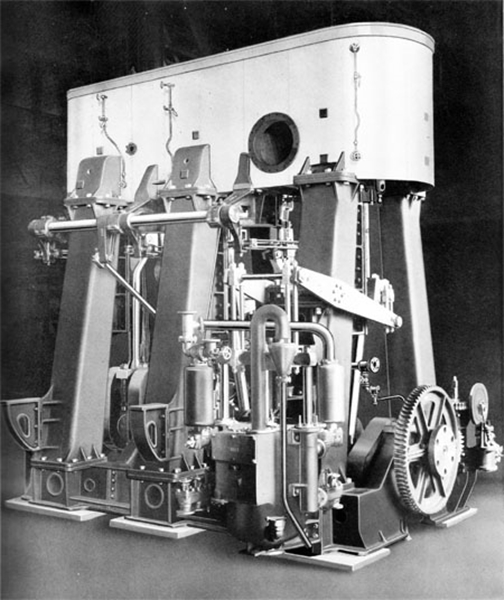

This image came from the Instructions for the

operation and maintenance of 2500 I.H.P.-24 1/2-37-70 x 48"-76 R.P.M.

vertical triple expansion marine steam engines for the United States

Maritime Commission EC2-S-C1 cargo vessels.

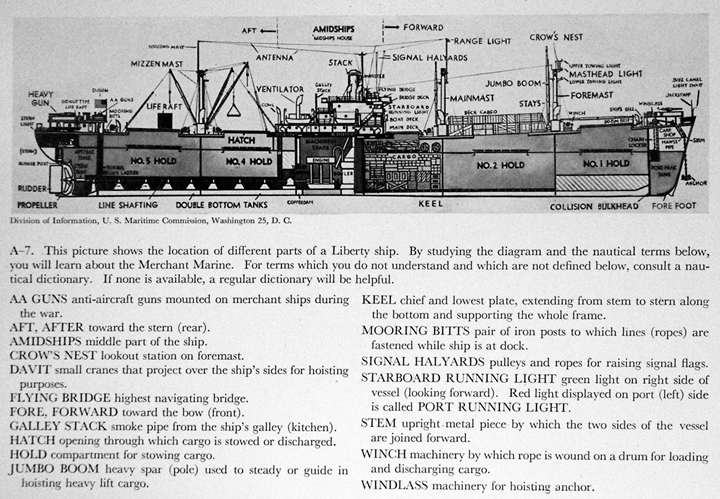

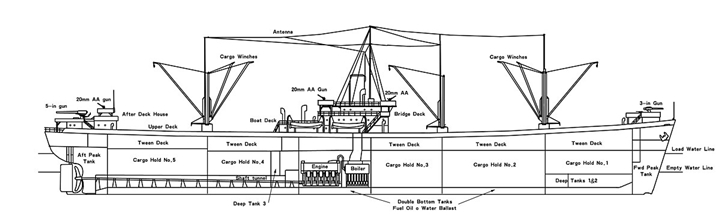

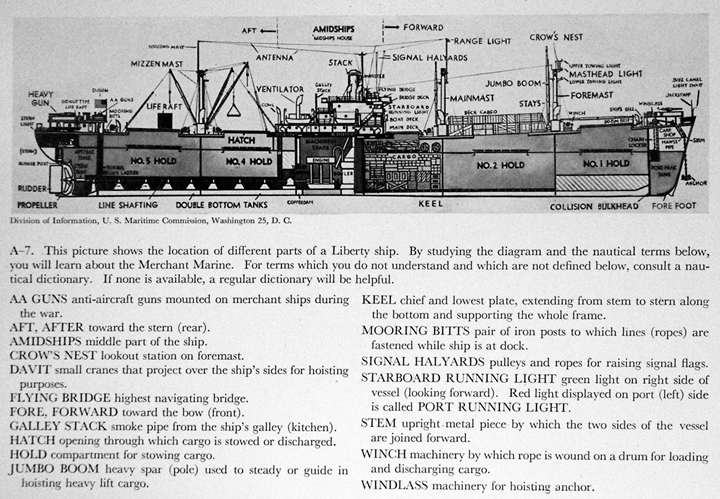

This launching of the Liberty ship James

Eagan Layne shows the type of vessel it was. Image courtesy of M.

Layne.

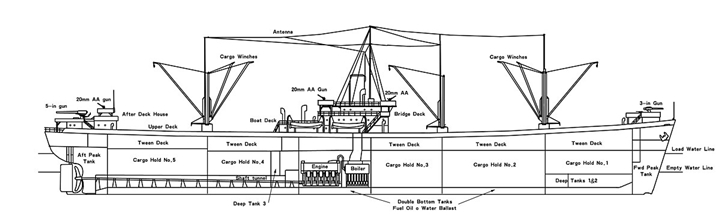

The engine was located in the center of the

ship. U.S. Maritime Commission image.

This image better shows that the propeller

shaft ran almost half the length of the ship. Image courtesy of

Wikipedia Commons.

Another diverse World War Two product of the

Iron Fireman Manufacturing Company was the T36 snow tractor. As

noted above, I photographed this at the 2014 MVP-HA National Convention

in Oshkosh, WI. Author's photo.

The T-36

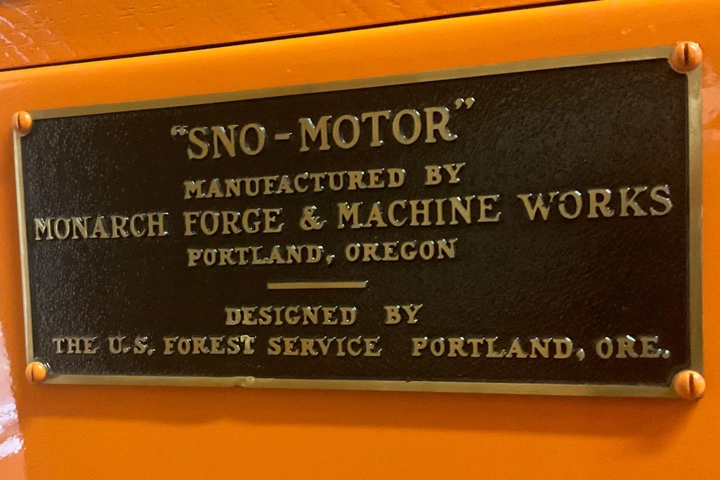

was based

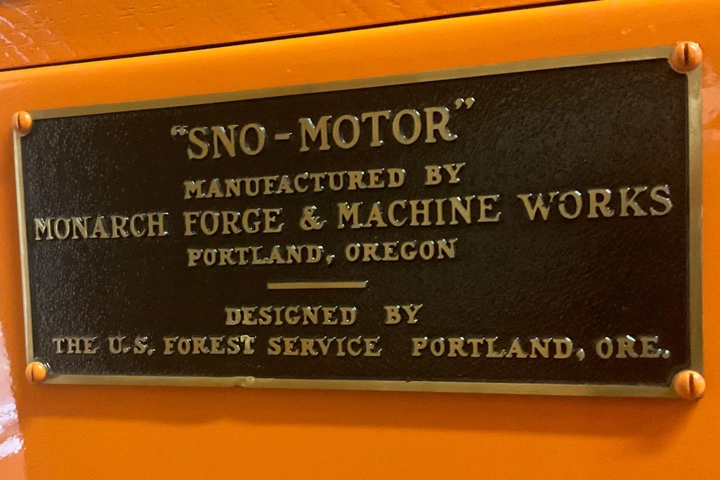

on the 1938 Monarch Sno-Motor developed by Theodore (T.P.)

Flynn who was a Forest Service employee. He was also a pioneer in

bulldozers and was involved in the creation of the Clark Airborne dozer.

Image courtesy of Silodrome added 12-8-2024.

Monarch Forge & Machine Works was still in

business and part of the Oregon War Industries, Inc. in Portland, OR.

However, it apparently did not have the capacity to produce the number

of T-36s required for the war effort. It only had $486,000 in

major contracts during World War Two. It could also have been

producing important forgings for the other company in the Oregon War

Industries, Inc.

Image

courtesy of Silodrome added 12-8-2024.

I was totally unaware of such a

vehicle and found this a welcome surprise at the convention.

Author's photo.

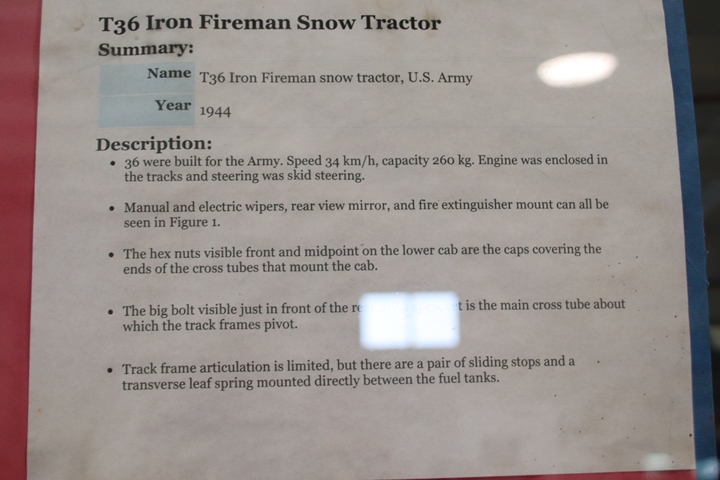

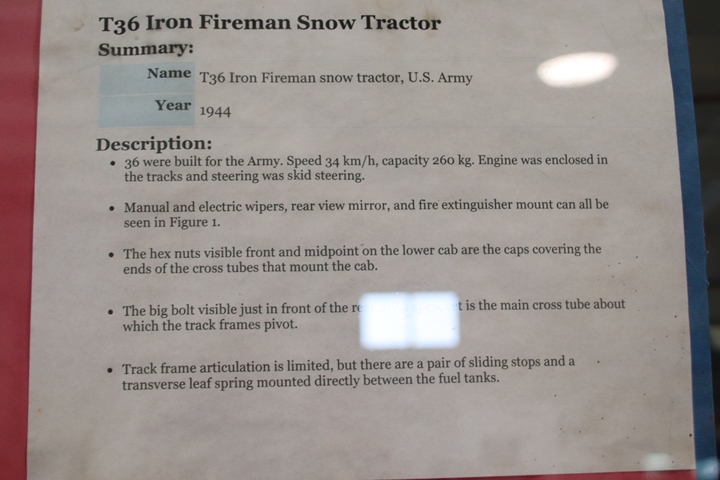

Table 3 shows that there were 36

accepted by Army Ordnance in 1944. Table 2 indicates the contract

amount for the 36 vehicles was $518,000 which is a cost of $14,889 per

unit. Author's photo.

This is one of four T36s that still

exist. Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

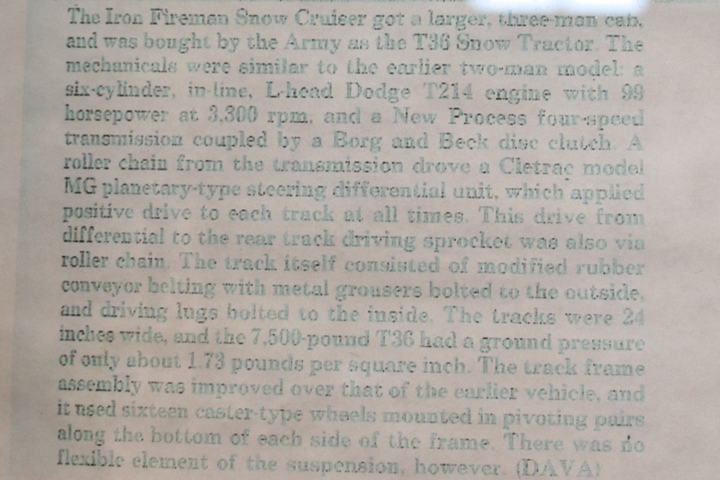

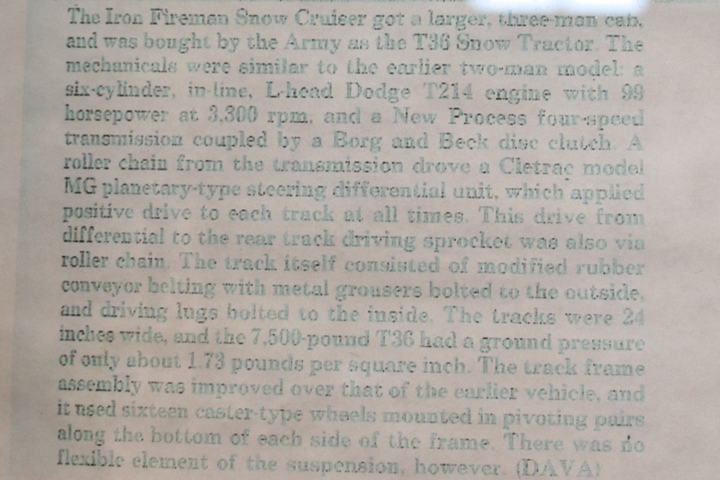

The owner had four information sheets placed

in one of the windows. I have included all four, as they are

comprehensive in providing information on this very rare and unique

vehicle. This one is from "U.S. Military Tracked Vehicles" by Fred

W. Crismon. Author's photo.

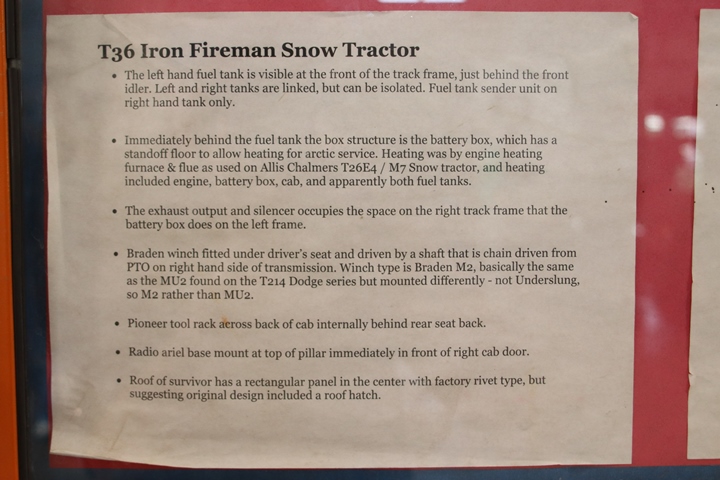

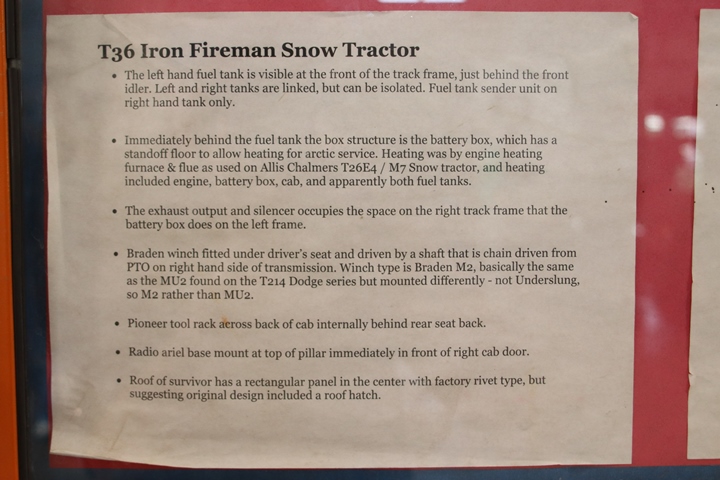

This and the next two information sheets are

by the vehicle's owner. Author's photo.

Author's photo.

Author's photo.

The Iron Fireman

Manufacturing Company Portland, OR Plant:

The original building at 984 SE 17th St.

Portland OR, was built in the 1920’s for the Iron Fireman. Two

Iron Fireman logos can be seen on the building. Image courtesy of

Iron Fireman Collective.

What is really cool is that the original Iron

Fireman Manufacturing Company building still exists and is in current

use. This photo replicating the photo above was taken by Google

Maps in June 2019.

The Iron Fireman Collective at 4784 SE 17th

Avenue, Portland, OR was established in 2016 as a tribute to the

original Iron Fireman factory building to provide spaces crafted for

makers, manufacturers, fabricators, innovators, and entrepreneurs. The

plant was fully renovated for modern day production. This 1920 146,000

SF building on the corner of SE 17th Avenue and SE Schiller Street

appears to be a nondescript two story restored factory building.

The building is in the same location it always has been. The

address system changed in the last 100 years. Image courtesy of

Google Maps.

This image of the back side of the factory shows the original red brick

that has not been repainted. Repainting old factories for being

repurposed is common as they make the buildings look better. Image

courtesy of Google Maps.

This and the next five photos are all

courtesy of Google Earth and give a 360 degree view of the factory.

All show that the Iron Fireman Manufacturing Company plant expanded to

fill one city block.

Iron Fireman ashtrays can be found on

today's online auction sites.

|